Moorfields building sets UK pile-loading record

|

Contents |

Outline

The construction of LandSec’s 21 Moorfields development has set the record for the most heavily loaded pile test of its type in the UK.

Structural engineer the Robert Bird Group was commissioned by LandSec to develop the structural and geotechnical engineering design of 21 Moorfields in London’s Moorgate area.

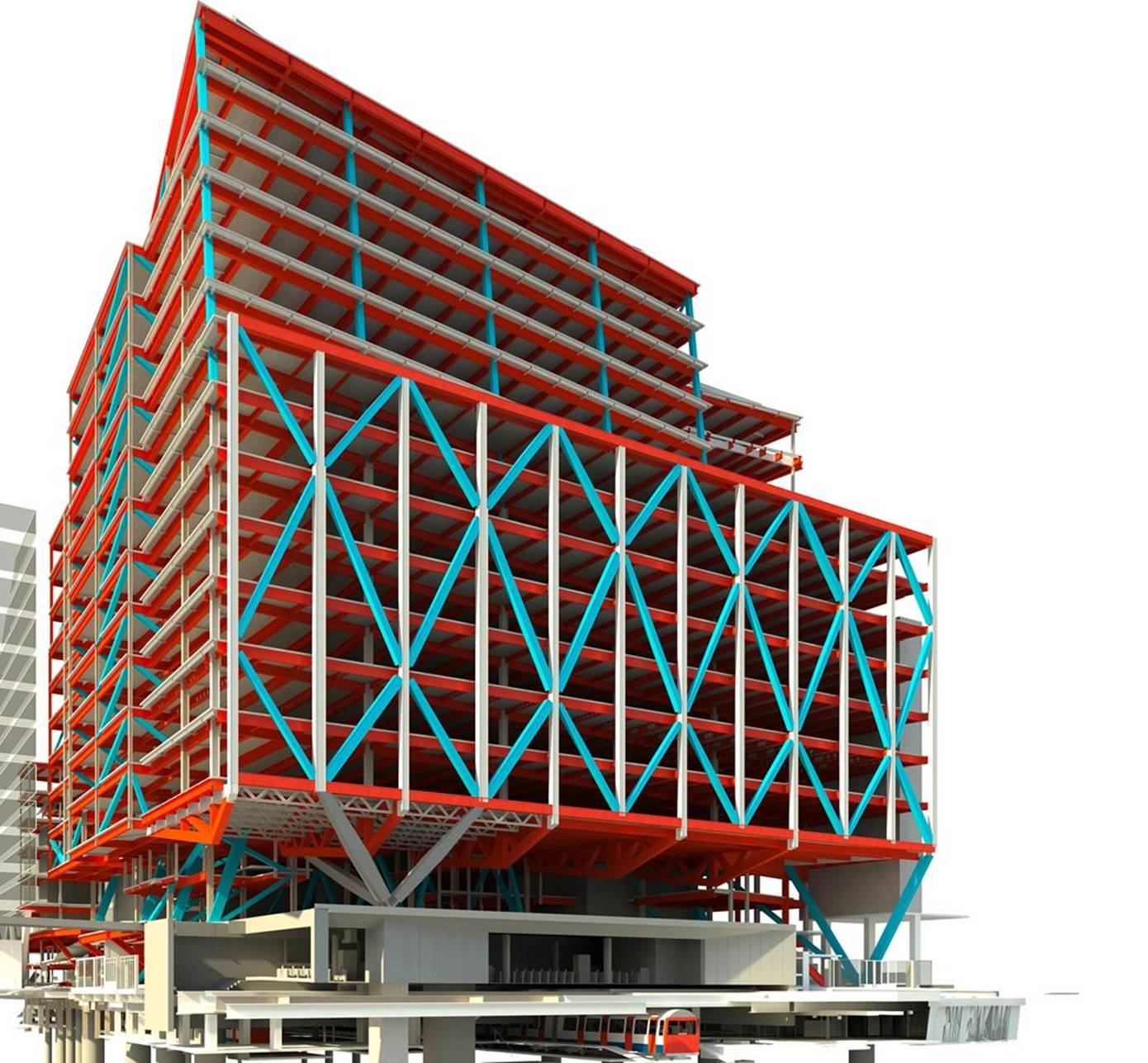

A complex steel frame

|

| Test pile operations taking place on site |

The proposed 16-storey (60,000 sqm) future London HQ for Deutsche Bank will clear span up to 55m over Moorgate underground station, which includes the Circle and Metropolitan Line, City Thameslink sidings and the new western ticket hall to Liverpool Street Elizabeth Line station, to avoid disruption to the stations during construction.

The complex steel frame uses a combination of long-span arches and transfer trusses to provide a coordinated temporary and permanent works solution to building over a live station.

|

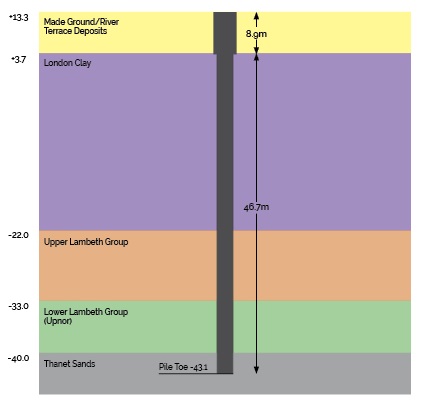

| Piling through the site's geology |

The key to unlocking the development lay in the foundation solution: the entire building is supported on only 15 new mega-piles of 1.8m–2.4m diameter that extend down to the Thanet Sand, more than 50m below the station.

The unfactored load carried by individual piles will be greater than 55MN, more than any other single pile in the UK, and equivalent to the typical load seen in columns of a 30-40-storey tower. To justify such an advanced foundation design, a pile test was crucial to confirm its performance under such large loads.

The roof of Moorgate station had insufficient capacity to support the major plant loads required to install the piles - a 140-tonne piling rig, 140-tonne crawler crane and ten wet 90-tonne bentonite tanks.

Collaboration

Robert Bird Group’s (RBG) construction engineering team developed the temporary works strategy to enable piling operations to be undertaken above the station roof using a steel grillage to transfer the plant loads to the existing station columns and their foundations. The grillage was designed for easy assembly and removal, and to optimise the programme and minimise environmental impacts on the surrounding neighbourhood.

RBG, Cementation Skanska, Mace and Geotechnical Consulting Group worked closely together throughout the development of the pile design and construction methodologies. This included the design of the pile test which used a bespoke 200 tonne, 6m-tall steel reaction frame to load a 1.2m diameter, 55m-long sacrificial pile to up to 50.5MN. The test pile included full-length instrumentation that allowed the team to determine how the load is shed along its shaft at various depths and at its base.

Testing

|

| The pile test truss |

The reaction frame was jacked against four of the permanent piles that were also fully instrumented. The jacks were individually controlled by ALE, the jacking specialist, throughout the 72-hour test with RBG on site to monitor the response of the reaction frame.

The test was completed with the pile head having settled by only 73mm under the maximum load, a load 25% greater than the failure load predicted using the conventional theory of deep piles in London. It also outperformed the settlements which were predicted to be more than 300mm. This result not only validated the pile design for the project but will also provide the industry with highly valuable information on the behaviour of very highly-loaded deep piles in Central London.

21 Moorfields is due to be completed in 2021 and will be the London HQ of Deutsche Bank.

Related articles on Designing Buildings Wiki

- Bearing capacity.

- Bored piles.

- Driven piles.

- End-bearing piles.

- Geophysical survey.

- Ground conditions.

- How deep should foundations be?

- Insitu testing of soils.

- Pile foundations.

- Pile integrity test.

- Piling equipment.

- Soil survey.

- Structural engineer.

- Tension piles.

- Testing construction materials.

External sources

Featured articles and news

Some of the articles relating to water, here to browse. Any missing?

Recognisable characters of Gothic architecture designed to dramatically spout water away from buildings.

A case study and a warning to would-be developers

Creating four dwellings... after half a century of doing this job, why, oh why, is it so difficult?

Reform of the fire engineering profession

Fire Engineers Advisory Panel: Authoritative Statement, reactions and next steps.

Restoration and renewal of the Palace of Westminster

A complex project of cultural significance from full decant to EMI, opportunities and a potential a way forward.

Apprenticeships and the responsibility we share

Perspectives from the CIOB President as National Apprentice Week comes to a close.

The first line of defence against rain, wind and snow.

Building Safety recap January, 2026

What we missed at the end of last year, and at the start of this...

National Apprenticeship Week 2026, 9-15 Feb

Shining a light on the positive impacts for businesses, their apprentices and the wider economy alike.

Applications and benefits of acoustic flooring

From commercial to retail.

From solid to sprung and ribbed to raised.

Strengthening industry collaboration in Hong Kong

Hong Kong Institute of Construction and The Chartered Institute of Building sign Memorandum of Understanding.

A detailed description from the experts at Cornish Lime.

IHBC planning for growth with corporate plan development

Grow with the Institute by volunteering and CP25 consultation.

Connecting ambition and action for designers and specifiers.

Electrical skills gap deepens as apprenticeship starts fall despite surging demand says ECA.

Built environment bodies deepen joint action on EDI

B.E.Inclusive initiative agree next phase of joint equity, diversity and inclusion (EDI) action plan.

Recognising culture as key to sustainable economic growth

Creative UK Provocation paper: Culture as Growth Infrastructure.